A touch screen is a type of electronic input and display panel. Using hand motions and fingertip movements, a user interacts with a computer, tablet, smartphone, or touch-controlled device by tapping images, manipulating objects, or typing text on the screen. The pressure-sensitive displays may be operated or interacted with either fingers or a pen.

To navigate a graphical user interface, touch screens are a convenient substitute for a keyboard and mouse. To avoid the necessity for touch-sensitive input, some gadgets also utilize touch screens with a network of infrared rays that detect a finger.

Talking about the uses of touch screens, today, touch displays are extensively utilized in consumer self-service kiosks, automated teller machines (ATMs), airline e-ticket terminals, retail stores, libraries, and fast-food establishments. The most popular method of input for mobile phones is undoubtedly touched displays.

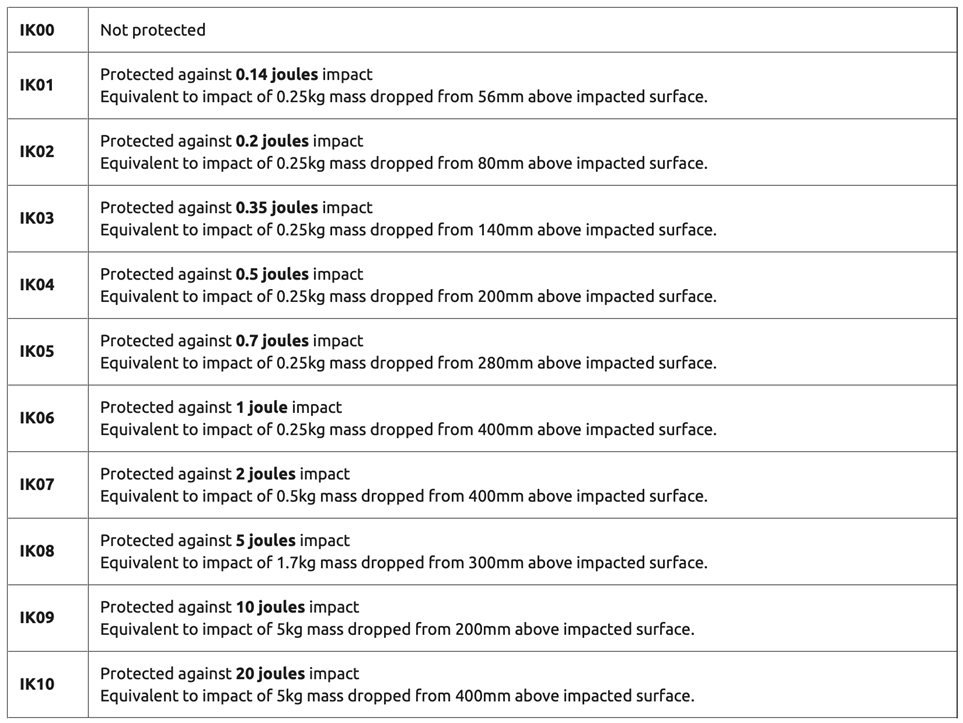

IK10 Touch Screen is a screen with a 10 IK rating. Impact protection is rated using the IK scale. A higher number indicates a more durable product that can resist a bigger impact on a scale from 1 to 10. The impact type under test is not as powerful as a sledgehammer force. An international numerical system known as IK Ratings is used to categorize the levels of protection offered against external mechanical impacts. It offers a way to describe how well an enclosure can shield its contents from outside influences.

The "Charpy Pendulum" impact tester is a technique used to conduct the IK impact resistance test. To create an impact that is measured in Joules, a steel hammer is dropped from a specific height.

According to the resistance level rated, the product is given an IK code after the test. There are 10 different codes, numbered IK0 through IK10.

While, IK01 offers impact-resistant to 0.14 joules, equivalent to a 0.25- kilogram load that was dropped 56 mm above the surface being struck. IK10 protection offers protection against impacts of up to 20 joules. Equivalent to the impact of a mass of 5 kg dropping from 400 mm above the surface being struck.

It takes little energy to make one joule. A typical illustration of one joule is the amount of force needed to raise a little apple (100 g, or 0.1 kg) to one meter in height while defying gravity (9.81 m/s2, or around 10 m/s2). Although the units for torque and joules are the same (1 kgm/s2 = 1 Nm), torque is a vector quantity of force applied at a distance, whereas joules are scalar quantities (they have both magnitude and direction) of force applied through a range.

Speaking about the history of IK Level or Rating, IK ratings are related to the European standard EN 62262 for touchscreens, which is the same as the international standard IEC 62262 (2002). This is a global numeric rating for the levels of defense offered by electrical equipment enclosures against outside mechanical impacts. It offers a way to describe how well an enclosure can shield its contents from outside influences. The European Standard BS EN 50102 first defined the capacitive touch panel IK Code (1995, amended 1998). The European standard was given the new number EN 62262 after becoming an international standard in 2002.

A piece of electrical equipment must meet the requirements of Standard EN 62262 for its impact strength or resistance to external mechanical stress when subjected to certain shocks. The EN 62262 standard simply specifies the impact amount of energy; the EN 60068-2-75 specification contains details on the test circumstances and process.

IK10 Touch Screens offer the maximum level of protection against shocks and impacts, making them ideal for outdoor and industrial use.

While EN 62262 specifies how enclosures should be mounted during tests, the atmospheric circumstances that should exist, the number of effects and their allocation, and the volume, style, material, dimensions, etc. of the different kinds of hammers designed to produce the required energy levels, IK ratings assist in classifying products based on their resistance to effects by kinetic energy.

These touch screens have been thoroughly examined. The "Charpy Pendulum Test" is used to evaluate the screens' robustness. In the IK test, an impact object is dumped onto the test location from a certain height with a predetermined weight and form, and an IK grade is given to them as a result. The screen with the highest rating, IK10, protects against 20 joules.

For this reason, taking the IK rating into account when buying a touch screen for any application is crucial. Based on your usage and intended use of the touch screen, the rating gives you an estimate of how much protection you need.

The energy gains every level more than doubles starting with IK class IK07. The demands on glasses are particularly high due to the exponential rise in impact resistance, which sets the highest possible demands on the material and integration process. Every little thing matter, especially in the particularly robust area of IK10 where the impact energy is from 20 joules. For the glass to have the best impact resistance, proper integration is a crucial need.

In essence, as little as feasible yet as much as essential, although sometimes, the issues are more complicated than the simple observance of a standard.

The crucial query is, "What else do you want to accomplish?"

We at EAGLETP are happy to help you resolve these problems and can swiftly and expertly offer you a cost estimation.

You should get an industrial touchscreen based on your demands as well. The touch screen can provide you with pertinent features and accommodate your job demands in this method. Strong functional and technical advantages underpin industrial touch screens.

Due to the need for toughness and durability in industries, the screen must be robust in addition to having excellent features. IK rating must be considered when discussing touch screens used in industrial settings. You can determine the precise amount of pressure a touch screen can withstand by looking at its IK rating. It is now simpler for you to select the ideal IK touchscreen for your industrial task. The display is often covered in a 6mm or 8mm layer of toughened glass to boost its impact and resistance to abrasion.

Toughened glass can be added to industrial screens in open-frame, panel-mount, and chassis-mount formats to increase IK protection and safeguard the asset. The severe circumstances they are used in, not vandalism, are what cause this damage. These displays are not just used in factories; they are also used in public spaces, such as ATMs and vending machines, which often feature a hardened open-frame display set behind a unique chassis.

Since IK10 provides exceptional protection against pressure up to 20 joules, and since we are aware that industrial works call for certain rugged and durable screens. IK10 touch screens offer excellent protection against a variety of high-level hits and shocks encountered in regular work because of their exceptional shock resistance.

The following list outlines the basic strategies to raise impact rating:

IK rating translates roughly to "impact protection." The touch screen may support a greater weight depending on the code of the IK rating.

Impact resistance works to guarantee that touch screens may be utilized in challenging conditions and provide excellent longevity. IK ratings range from 1 to 10, with a higher value suggesting a product that is more durable and can resist a bigger impact. The impact type under test is not as powerful as a sledgehammer force. IK10 can withstand 20 joules—the force of 5 kg being dropped from 400mm—without being damaged.

The level of protection offered by displays or touch screens against external mechanical damage is measured using the IK rating (Impact Protection rating). It establishes a product's resilience against impact damage.

A powerful, durable illumination is essential to provide a successful, risk-free operation in industries or at work where applications frequently involve large equipment, which raises possible dangers.

You must pay close attention to how the product is applied and if it has been subjected to demanding usage and effects. If you need a performance that lasts longer, make sure you research to find the best quality-to-cost ratio for your goods. It is crucial to take into account the environment in which the product will be used. Together, these elements will affect how well your product performs.

Eventually, if you want to get a long-lasting device that safeguards your integrations, you must select a touch screen with an IK10 rating, which is the maximum degree of IK rating.