Digital electronics are the backbone of modern-day civilization without any doubt. Whether it is household appliances, office equipment, industrial machines, or military hardware, digital electronic circuits run the show.

The advent of smartphones has accelerated the pace of digitization and brought forth a digital revolution in a matter of a few years. Not so long ago, people used to interact with their phones through buttons. However, rapid advances in display technology have enabled users to interact with their phones through touch screens. Today even the lowest-end smartphone devices feature touch screen displays. The popularity and widespread adoption of touch screen displays are not only limited to smartphones. Wearable devices like smart-watches and fitness trackers also boast touch screen displays.

In this article, we will explain the key differences between resistive and capacitive type touch screen displays.

The user interfaces of earlier computers and electronic devices largely consisted of buttons. A typical example is a keyboard that is still used as the primary input device for computers and laptops. However, as the size of electronic devices started shrinking, button-based interfaces soon became a liability that consumed precious space. Touch screens were then presented as the interface of choice for space-constrained electronic devices. The inclusion of touch screen interfaces in smartphones kick-started the era of mobile phones and handheld computing devices.

Any display device that allows the users to interact with electronic devices through the touch of their finger or a stylus fall under the category of touch screen displays. Touch screen displays are an efficient and elegant alternative to keyboards, mice, and joysticks for navigating the graphical user interfaces of digital devices. Today a vast array of electronic devices feature touch screen displays including smartphones, tablets, notebooks, smart watches, refrigerators, and TVs.

Multiple touch screen technologies are available in the market today. There are four major types of touch screens.

Resistive and capacitive are the most widely used touch screen technologies. The type of touch screen display determines several factors including actuation force, response time, operating life, sensitivity, multi-touch operation, and image resolution.

A resistive touch screen display takes pressure as input. This pressure can either be applied through a finger or a stylus device.

The resistive touch screen is constructed using multiple layers of plastic and glass. The front layer is made from scratch-resistant glass while the bottom layer is made from chemically toughened glass. Both the layers are coated with a conductive material (Indium Tin Oxide or ITO). The glass and plastic layers are separated from each other through air gap spacers.

When a user applies pressure on the front plastic layer, a voltage divider circuit is formed. The measured resistance of the voltage divider circuit provides the exact location of the touch point. Hence, this type of display essentially measures the change in resistance value to determine the point of contact.

Salient advantages of resistive touch screens are:

While most modern smartphones feature capacitive touch screens, resistive touch screens still find their applications in gaming consoles, home appliances, and industrial HMIs (human-machine interfaces).

Some of the drawbacks of resistive touch screens are:

Unlike resistive touch screens, capacitive screens do not require pressure input for sensing touch. Capacitive touch screens make use of the capacitance of the human body for the measurement of the touch point.

In a capacitive touch screen, a glass layer is coated with a transparent conductor like ITO (Indium Tin Oxide). The capacitance of the human finger causes a change in the electrostatic field of the touch screen. This change in capacitance is then measured by a microprocessor-based electronic circuit to determine the exact position of the touch point on the screen.

Due to their low actuation pressure and high resolution, capacitive touch screens are widely used in the latest smartphones and tablets. Manufacturers are now developing even thinner capacitive touch screens for enhanced user experience. An example of such a display is the Super AMOLED touch screen developed by Samsung using in-cell technology.

Key advantages of capacitive touch screen displays are:

The major disadvantages of capacitive touch screens are:

Capacitive touch screen technology is further divided into two sub-categories:

In surface capacitance touch screens, the base glass layer is coated with transparent conductive material. Electrodes are then placed on all four corners of the conductive glass surface. All four electrodes are provided with the same voltage so that a uniform electric field is formed. Current from all four electrodes flows towards the point of contact when the finger of a user touches the screen. The ratio of these currents provides an accurate measurement of the point of contact.

Major advantages of surface capacitance touch screen technology are:

Disadvantages of surface capacitance screens are:

Projected capacitance is the most widely used touch screen technology because of its widespread use in smartphones and tablets. The structure of the projected capacitance screen is more complex than the surface capacitance screen. Projected capacitance screens consist of multiple grid-structured layers with X and Y electrodes. Hence, projected capacitance touch screens consist of glass, adhesive, and electrode layers. The X and Y electrode layers form a grid or matrix-like structure. When a user puts his/her finger on the screen surface, the electrostatic field of electrodes changes. This change in the electric field is detected by a touch sensor and hence, the position of the touched point is determined.

Major advantages of projected capacitance touch screens are:

Disadvantages of projected capacitance screens are:

Project capacitance technology or PCT uses two different types of touch sensors:

As described earlier, projected capacitance touch screens consist of X and Y layers of electrodes. At each intersection of the rows and columns of the matrix, a natural capacitor is formed. When a voltage is applied to the electrode rows and columns, an electrostatic field is formed and capacitors get charged. The electric field of the human finger causes a reduction in the mutual capacitance of the local electric field. This change in the local electric field is detected by a controller to determine the accurate position of the touched point. Mutual capacitance sensors allow for multi-touch function and are also able to detect gloves and styli.

Self-capacitance sensors also work with the electrode grid however the rows and columns operate independently. These sensors measure the capacitive load of the finger using a current meter or an RC oscillator. The position of the finger is measured independently by the rows and the columns. Some of the phones that use self-capacitance sensors include Sony Xperia Sola, Samsung Galaxy Note 3, and Samsung Galaxy S4. Self-capacitance touch screens are more sensitive as compared to mutual capacitance touch screens. Due to this reason, they are mostly used for single-touch operation, simple gesturing, and proximity sensing.

| Feature | Resistive Touch Screen | Capacitive Touch Screen |

| Production cost | Production cost is low | Production cost is high |

| Actuation pressure | High actuation pressure is needed | No actuation pressure is needed |

| Stylus | Easily work with styli | Do not work with regular styli |

| Multi-touch | No | Yes |

| Texture | Comparatively rough | Smooth |

| Width | Higher width | Lower width |

| Resolution | Comparatively low | Comparatively high |

Resistive and capacitive touch screens are widely used in modern electronic devices. Due to their superior performance, capacitive touch screens are mostly used in smartphones, tablets, notebooks, and other high-end consumer electronics. Capacitive touch screens are thinner, require low actuation pressure, have better response time, support multi-touch, and offer enhanced image resolution.

Resistive touch screens might not be as sophisticated as their capacitive counterparts, but they do have their own advantages. The most significant advantage of resistive screens is their low production cost. Moreover, they also work easily with styli and gloves which capacitive touch screens don’t. Resistive touch screens are mostly used in low to mid-tier electronic devices such as petrol filling machines, copier machines, fax machines, bank ATMs, and industrial panels.

If your application does not require high-end features then resistive touch screens are a cost-effective solution for you. However, if your application demands higher image resolution, faster response time, and low actuation pressure then you should opt for capacitive touch screens.

Touch screen interfaces have become an integral part of modern electronic devices. Touch screens offer an elegant and efficient solution for human-machine interaction. In this article, we have explored the differences between two major touch screen technologies i.e resistive and capacitive displays. Resistive touch screens offer lower cost and work smoothly with styli and gloves. Capacitive touch screens, on the other hand, offer the advantages of multi-touch, high image resolution, fast response time, and sleek dimensions. Resistive touch screens are mostly suitable for lower-end displays while capacitive touch screens are usually employed for high-end applications.

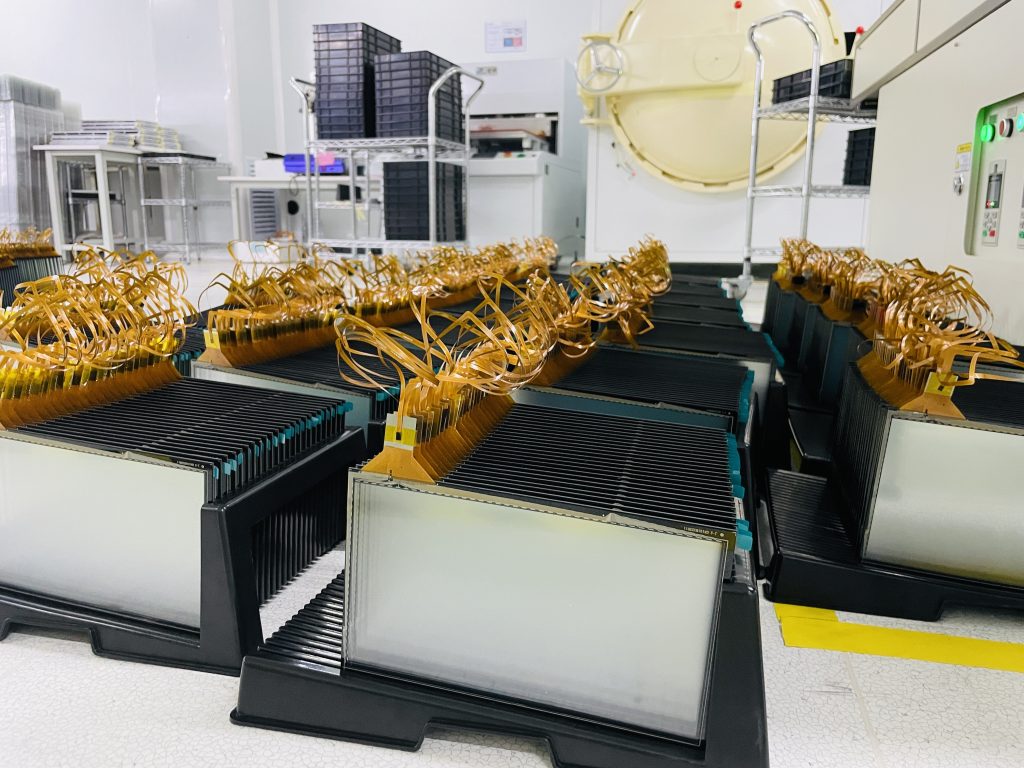

Eagle Technologies is a market-leading touch screen solution provider and manufacturer based in China. With its cutting-edge R&D and highly skilled team of experts, Eagle Tech offers high-quality and innovative solutions in the domains of resistive touch panels, projected capacitive touch panels, TFT LCDs, outdoor displays, and customized display solutions. Eagle Tech offers a one-stop solution for all your touch screen display needs.